Fatigue design of unpreloaded bolts (threaded rod)

I always thought that “fatigue design of unpreloaded bolts” was an oxymoron.

Isn’t fatigue design of unpreloaded bolts is a contradiction?

Not preloading a bolt is the exact opposite of what is required to prevent fatigue failure.

Would you drive a vehicle that did not have precisely torqued wheel studs?

A preload is necessary to reduce the stress range thus extend the fatigue life – and distance that can be travelled before the studs fail and wheels fall off?

(I am not referring to nuts tight enough only to prevent them loosening. If nut loosening was the only factor, then lock nuts would be used).

In the late 1960s, early 1970s, every self-respecting teenage Mini owner wanted to “widen” his wheels. (I was about to say “boy-racer”. However, in today’s woke world, such a term would now enrage the thought police). Wide wheels looked cool. Cornering speeds were even higher. Wheel “widening” became less common among teenagers when insurers started charging much higher premiums for vehicles with modifications.

Methods of wheel “widening”

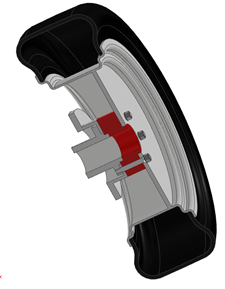

In principle, it could be said that there are two methods to widen wheels. One method would be to use a spacer and long studs. (Method 1 below).

Another method would be to use long studs with backing nuts. (Method 2 below).

Both methods would move the wheels outwards thus “widening”.

Which method would you use? What are the theoretical and practical reasons for choosing one method over the other?

Selection of wheel widening methods

A practical reason for choosing one method rather than the other might be alignment. How can you ensure all backing nuts are perfectly aligned with every other? What happens if one nut is out-of-plane with the other nuts? Even if all nuts were in the exactly the same plane, what happens if the plane is not normal to the wheel axis?

Theoretical reasons for your design selection might include the effect of the imposed loads. Even if the vehicle only travels in a straight line, weight loads reverse with every cycle of wheel rotation. Constantly changing and reversing loads means that the risk of fatigue failure needs to be considered? Which parts of the design would be be most at risk from fatigue?

How do stud axial and bending stresses vary?

Fatigue life of non-welded parts depends on stress range and mean stress.

What is the mean axial stress for the stud bolt on the inside of the backing nut? Particularly if one backing nut is slightly out of alignment? How would you know? Could you measure the installation errors or measure the stud load?

What effect would nut thread tolerance, thread wear, thread deformation and corrosion products have on axial position of individual backing nuts? How would thread fit and clearance of one backing nut change the mean stress for a group of studs?

Conclusion

By now you will be asking why I am asking such stupid questions.

Surely, the answer is obvious?

One method is supported by sound practical and theoretical reasons?

The other is totally impractical. Its design cannot be justified by normal engineering methods?

Failure would be certain if stress ranges exceeded endurance limits and the number of load cycles was high enough?

Now that you have thought about your Mini car wheels, what about other structures using similar design principles?

What happens if the other structures were also subject to cycling loads – but imposed on unpreloaded bolts?

High Mast Light Poles perhaps? Small wind turbines? CCTV towers and mobile masts? How do you prove they are safe? What is the fatigue life of their unpreloaded anchor bolts?

How many motorway lanes would be blocked if they did not remain upright?

If you are still interested, please down the file below. Comments and discussion would be very welcome.

Andrew Weighell [email protected]