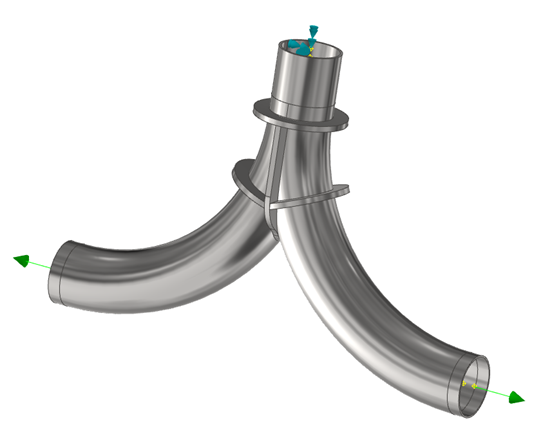

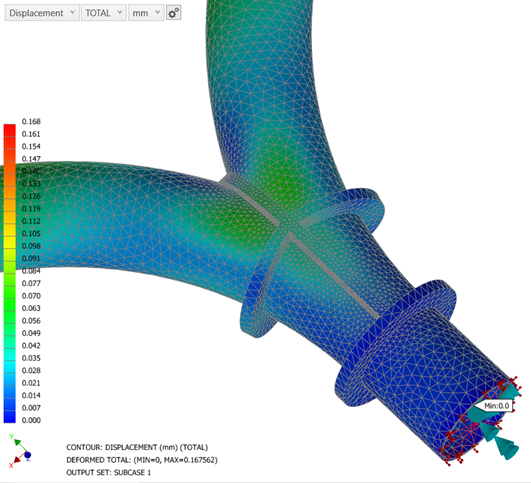

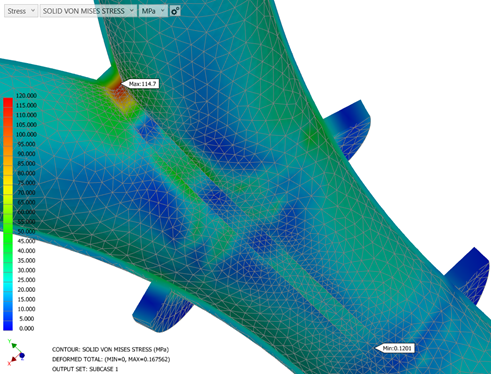

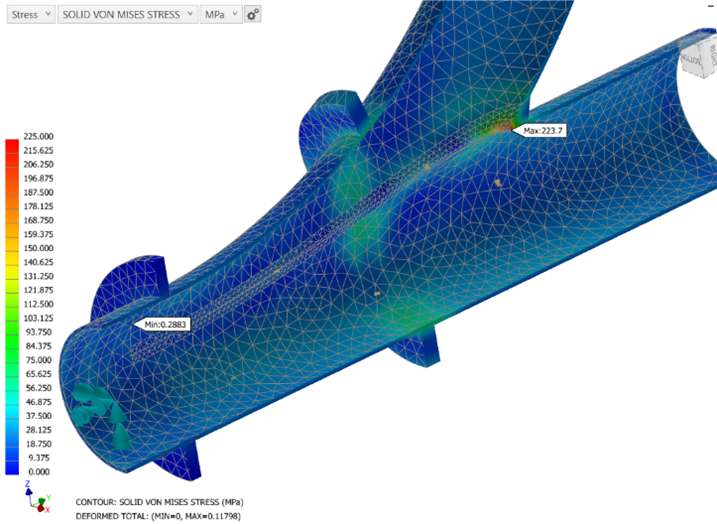

1. Swept Y Fitting with rib reinforcement

The internal surface of the longitudinal web matches the pipe bore. All through-wall welds are full penetration. The radial width of the longitudinal web at the crotch is reduced to enable full weld access. Reduction of web radial width at weld crotch is compensated for by wrap-around ribs.

A key design requirement was to maintain a constant pipe bore. i.e. Using thicker wall pipe to provide reinforcement would have reduced the pipe bore.

Note The internal surface profile follows the pipe bores despite the impression given by the mesh.

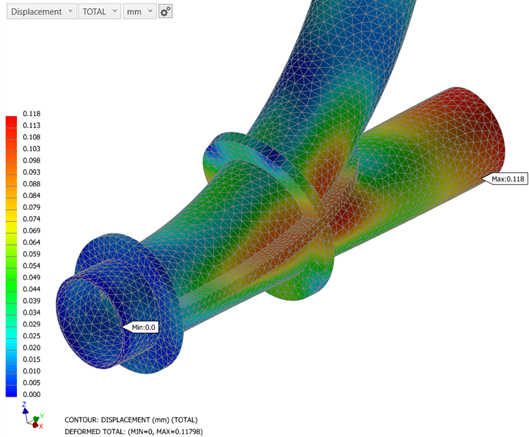

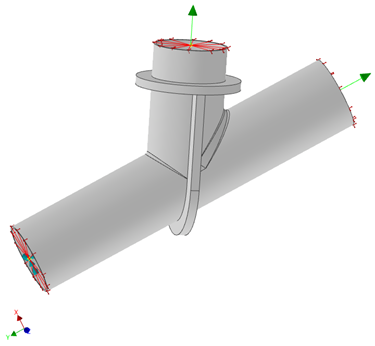

2. Equal Swept Branch

Reinforcement of the equal swept branch follows the same principle as for the equal swept Y above. i.e. The internal surface of the longitudinal web reinforcement follows the pipe bore. The only difference is that the longitudinal web is cut from a rolled plate.

The swept branch is a more severe design than the swept Y because the longitudinal length of the “header opening” is longer. i.e. More reliance is placed on the web reinforcement.

All welds are full penetration.

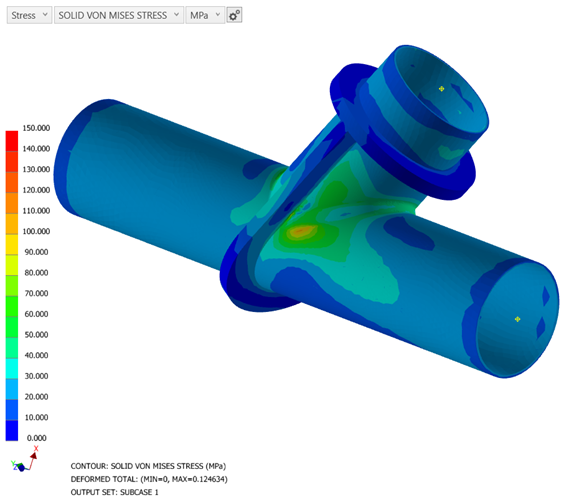

3. 60 deg branch

Key design requirements were the same as the Swept Y and Swept branch fittings above. i.e. Full penetration welds and constant internal bore with the connected pipe. The weakest part of a pipe branch are the “flanks” at the furthest extremity of the branch profile. i.e. The points on the side of the header at which the header would bulge. External reinforcing plates are added directly over the location most prone to bulging.

The point of maximum bulge is not on the exact centreline intercept of the branch. Theoretically, the reinforcing rib should be at a slightly large angle to the header. However, such a design would not win any friends from the fabricator.

The external reinforcing plates are added after completion and NDT of the the through wall branch welds.

Note The header length of the fitting as fabricated will be much shorter than for the FEA model. i.e. To give access for clean-up and internal inspection to the the branch welds.