2. Repad design

1. Introduction

If you asked 5 pipe stress engineers for their opinion on any subject, you would get 5 replies. Everybody has their own preferences. That is why pipe stress can be so interesting.

Who is correct? Everybody believes they are. Everybody can justify their preferences! Including me.

There are very few design solutions that are either perfectly correct or completely wrong. There are huge grey areas in all parts of piping engineering.

One subject that will have pipe stress engineers expressing their opinions are reinforcing pads (repads) for trunnions.

Are ring type repads better? (As you used for reinforced branches?)

Are pad type repads better? (Without the hole?)

Examples of ring type repads for both branches and trunnions are shown here.

A drawing for a pad type repad is shown in Fig 2 here.

I have my own opinion about which option I would choose. However, I do not want a bust-up! Therefore, I will only list some of the factors that I think might be considered.

2.1 Repad overall shape

Repad overall diameter and thickness are normally an exception to the rule. Everybody can agree.

a) Outside diameter = equal to twice the branch diameter. (The same as for reinforced set-on branches. It is as good a size as any so no need to change).

b) Thickness equal to the header. (Cut from spare header material).

2.2 Ring type – pros and cons?

The following are a few factors that might be considered for ring type repads.

- Lower stresses than for full pad type at smaller ratio trunnions?

- More expensive than pad type? i.e. More cutting and weld preparation.

- More effort to align and mate flush with header around both hole and outer edge.

- More welding.

- More complicated weld shape on the inside edge of the repad opening.

- Two step NDT (Non Destructive Testing) before and after fitting of pad. i.e. The trunnion-to-header weld has to be completed and NDT before the repad can be fitted.

- It is less easy to repair the weld on the inside of the pad. i.e. The weld is a circular groove. Accessed using an angle grinder needs more effort on smaller trunnions.

- The weld shape of the inside pad weld has got to be assumed for purpose of FEA. i.e. To account for cross sectional shape and fit-up tolerances.

- The highest stresses are in header wall or in welds directly connected to the header wall.

- Weld cracks from the most highly stressed welds could run through the header wall.

2.3 Pad type repad – pros and cons.

The following are a few factors that might be considered for pad type repads.

- Cheaper. i.e. The repad is only cut around its outside edge.

- The trunnion does not need to be same quality material or weld material as for welded connection to the header. i.e. The trunnion is not welded directly to the header.

- The trunnion does not need to be a pipe section? Sometimes an open section trunnion is preferred. Maybe corrosion is a concern? Maybe you have reasons not use a vapour phase inhibitor to prevent hidden internal corrosion?

- Minimal weld preparation is required other than around the outer square edge of the repad.

- Easier to align repad flush with header? i.e. Only the outside edge has to be in contact with the header.

- The weld shapes are simpler?

- Easier access to all welds for welding, NDT and repair? All welds can be accessed with an angle grinder

- One step NDT when all work on the trunnion is complete.

- The highest stresses are in the non-pressure parts. The high stress areas are subject to less risk of thinning due to internal header corrosion.

- Lower stresses in header wall even if the stresses in the trunnion are higher than for ring type. i.e. More margin for poor repad fit-up.

- Less risk of weld cracks from the most highly stressed welds running through header wall.

3. Numerical example to compare repad designs

3.1 Introduction

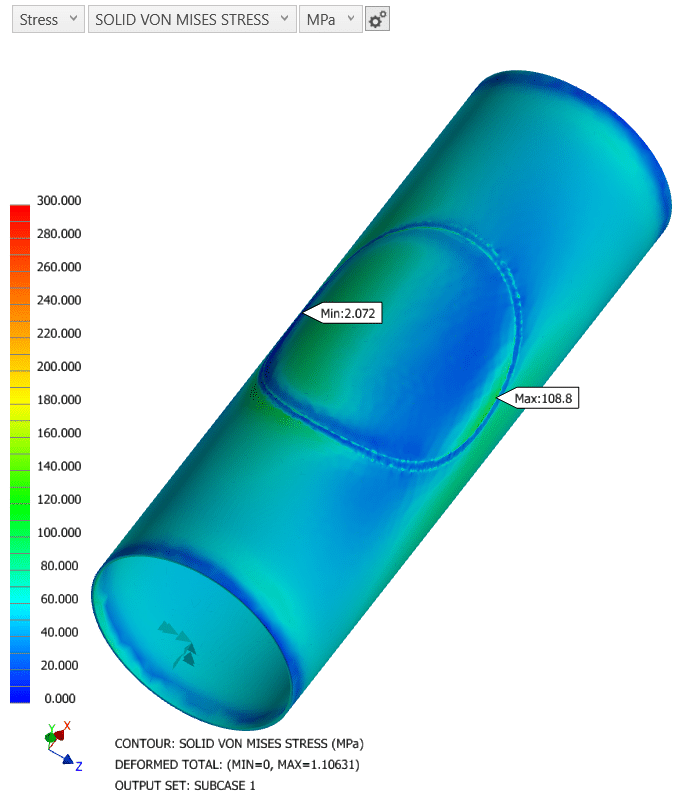

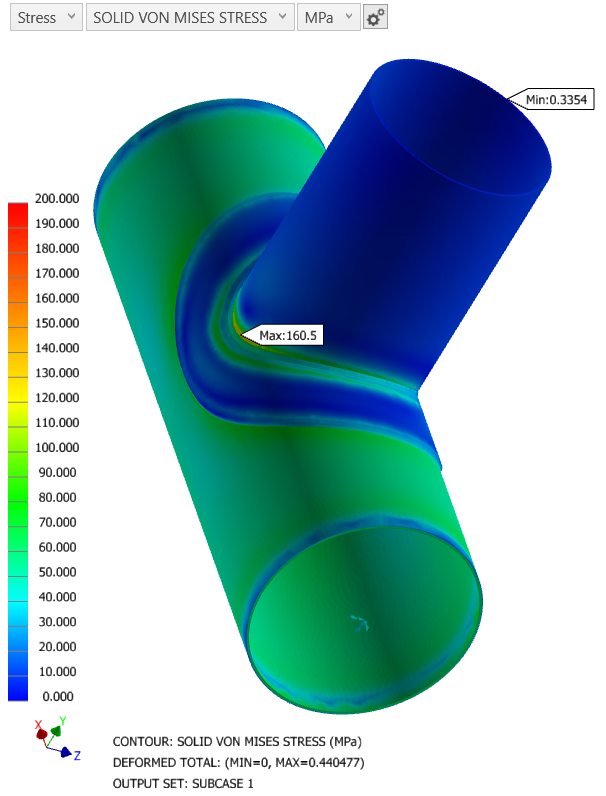

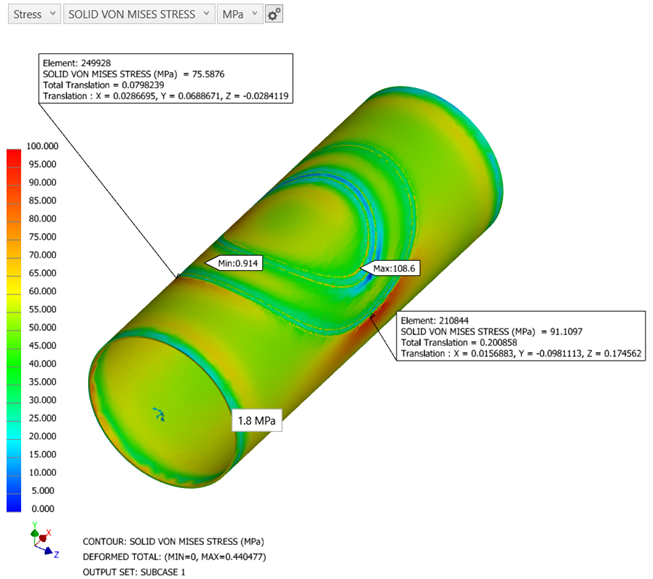

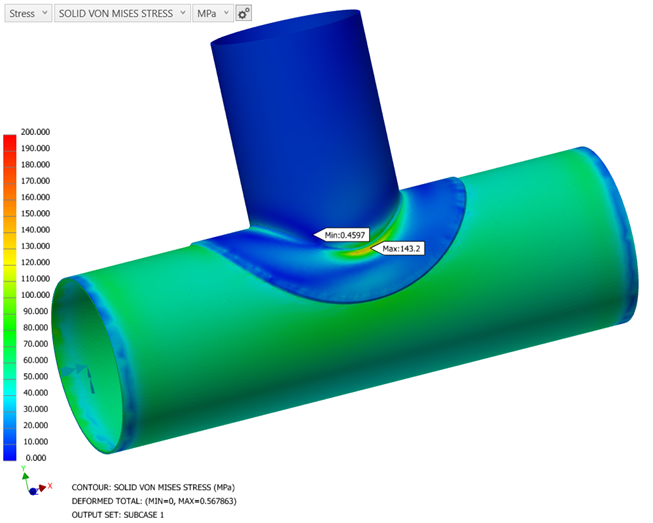

Two trunnion calculations are included below to compare ring and pad type repads. The design and loadings are identical. The only difference is repad type. One is a ring type. The second is a pad type.

All details, including sizes and loads are for purpose of calculation.

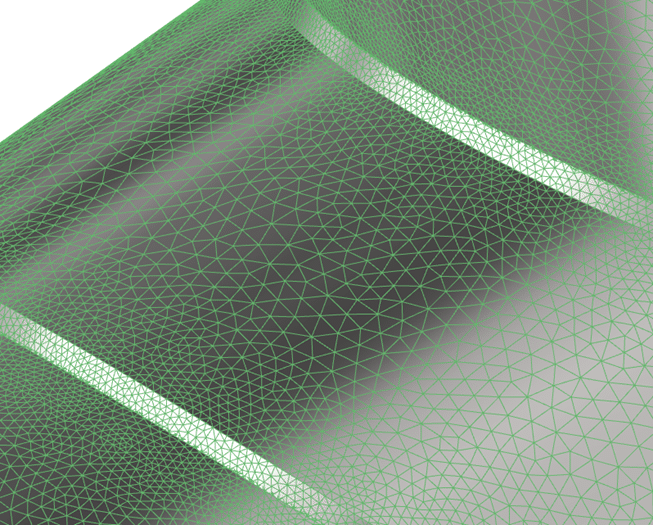

3.2 FEA Model

| FEA Software | Autodesk Nastran 2022 |

| Model type | Linear static |

| Elastic modulus | 193 GPa |

| Mesh size (Overall) | 15 mm |

| Mesh refinement | 2 mm at all welds and part contact |

| Mesh growth | 1.08 |

| Part contact | Bonded at welds and end of trunnion. No contact between inside of repad and outside of header. |

| Trunnion sizes | DN200 Sch 10S, 500 mm long from centreline of header. (Results Fig 3-6) DN250 Sch 10S, 500 mm long from centreline of header. (Results Fig 7-10) |

| Header size | DN300 Sch 10S, 1000 mm long, |

| Constraints | Header anchored at one end only. |

| Loads | Internal pressure = 1.8 MPa Header pressure thrust = 140141 N applied at free end of header. Trunnion forces = 7500 N longitudinal and 7500 N lateral (resultant 10.6 kN) applied at 500 mm from header C/L. |

3.3 Results

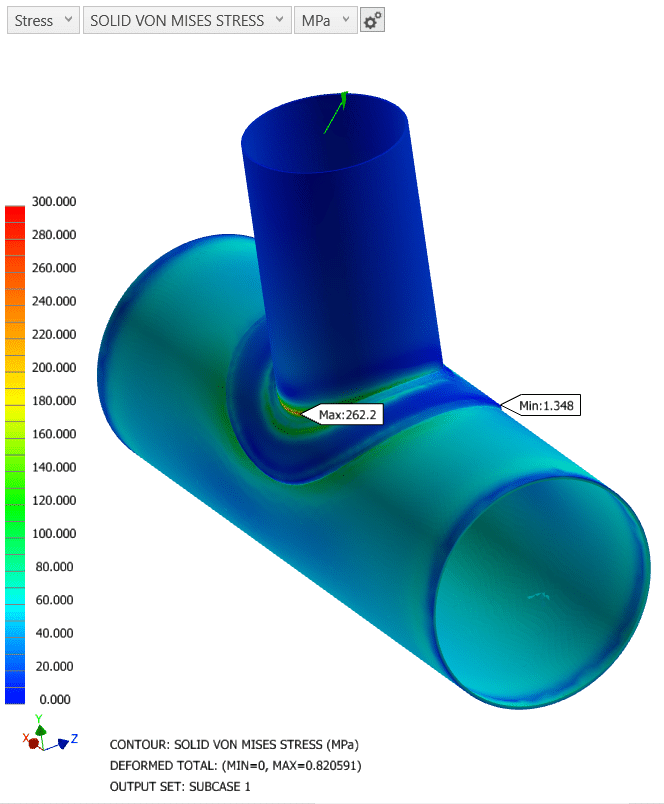

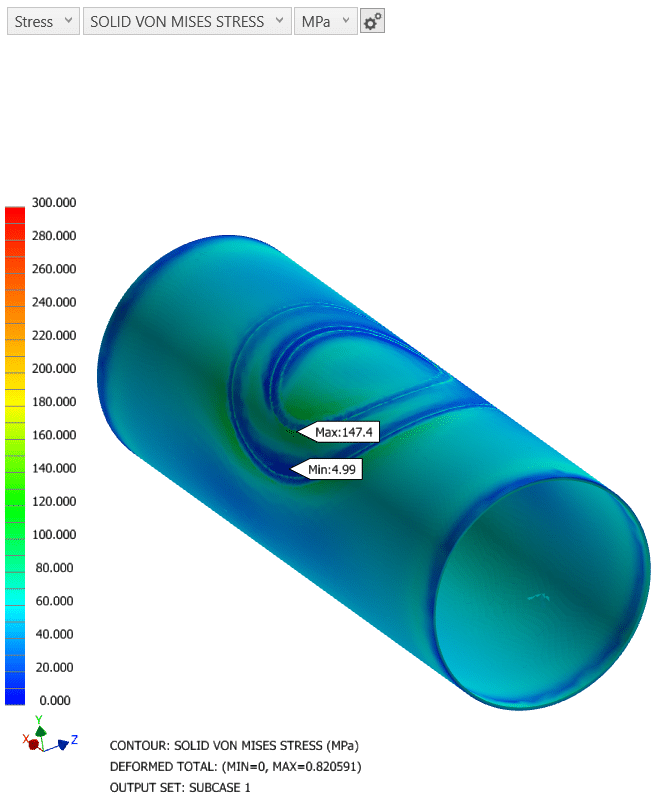

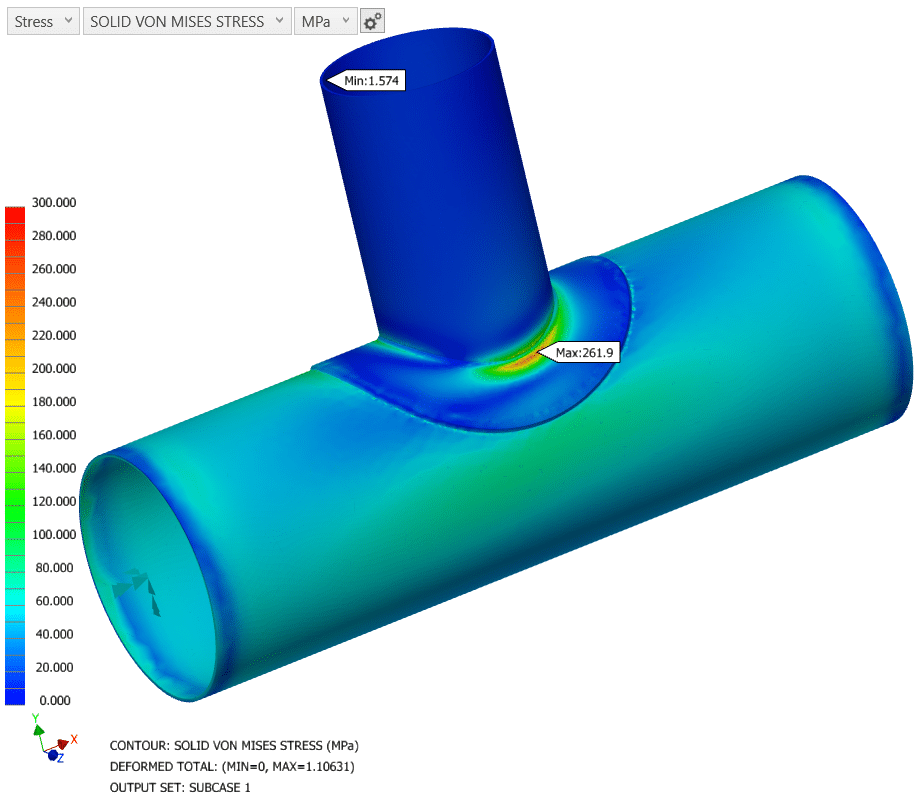

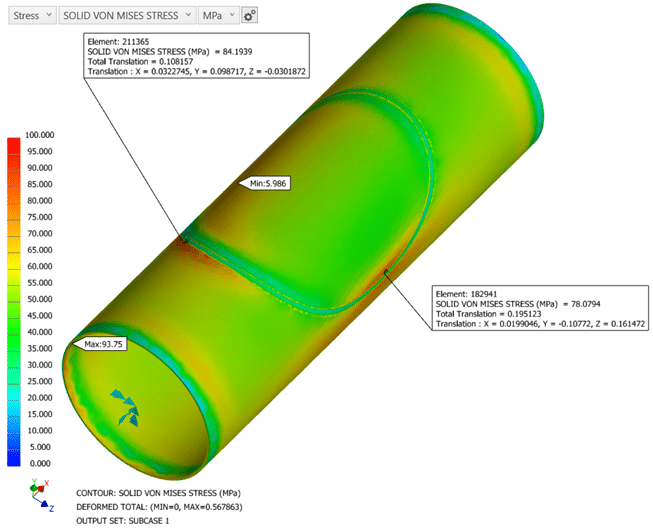

The following results are intended for comparison only. The loads, constraints and mesh sizes are identical. The only differences are the size and type of repad.

a) DN200

Similar maximum stress for both pad and ring type repads.

Stresses in welds directly connected to the pressurised header are lower for the pad type repad.

b) DN250

Lower maximum stress for the pad type repad.

Stresses in welds directly connected to the pressurised header are lower for the pad type repad.

c) DN150 (Results not included below).

Higher maximum stress for the pad type repad – but only in the repad away from the header weld.

3.4 Discussion

Note ! The calculations discussed here are based on a particular load and pressure for relatively thin pipe. Thicker pipe with different load combinations will give different results. Conclusions might be different.

Pad type repads appear to show lower overall stresses than ring type repads at larger trunnion-to-header size ratios.

Pad type repads appear to show lower stresses in the pressurised header.

3.4 Recommendations

The choice of repad type should be whatever the pipe stress engineer believes is the most suitable for his application. I would not want to start WW3 by suggesting either one type or the other.

3.5 Final thoughts

I will only make one suggestions for trunnions fitted to straight pipe. It will risk somebody’s wrath.

FE calculations for repads should not treat repads as though they are localised areas thicker header.

Analysing two layers of material with an unknown spacing as a single homogeneous layer is a theoretical and practical non-sense – in my humble opinion.

Even treating repads as separate layers and ignoring the potential for a gap is a leap of faith. (Hence the reason to minimise stresses at welds between pad and header).

The closeness of fit between a repad and the header depends on the skill and care of the fabricator. Even matching a cylindrical pad to a cylindrical header without a gap at the weld can sometimes be a challenge.

3.6 Repads of any type fitted to elbows.

This is not really part of the previous discussion. I will throw this hand grenade for good measure.

In my personal experience, I would never use a repad on anything but straight pipe. I would argue that it is a fantasy to expect that a repad can be fitted to an elbow. I have only seen repads “fitted” to elbows on one project. I have seen better fitting lids around the tops of pork pies. Even forged elbow repads are not guaranteed to fit perfectly. i.e. The elbow design standards do not specify the geometry of the elbow surface between its butt welds. e.g. ASME B16.9.